SMALL–MEDIUM-LARGE SCALE BIOMASS POWER – BASED ON MODULAR CONCEPT

CAPACITY-50Nm3/hr to 8000Nm3/hr – 60000Kcal/HR to 10,000.000Kcal/HR – 5KWE to 2000KWE GASIFIER'S TYPE: Fluidized Bed -- UPDraft / Down Draft / Twin Fire Fixed Bed Gassifier

WASTE HANDLED |

- | Rice Husk , Wood Chips, Saw Dust Bark, Wood Waste Forest Residue, Rice Straw, Wheat Straw, Cotton Straw, Corn Stalk Corn Cob Bagasse Peat Cocoa Husk,Coconut Shell , Bamboo Waste Willow ,RDF Pellets ,Empty Fruit Bunch Palam Kernel Paper Mill ,Shell Waste etc |

SALIENT FEATURES |

- | Faster & more precise Temperature Control- Handling of Irregular shaped feed stock - Rapid start up and program change Low Pressure drop allowing producer gas recirculation for max Turn Down Ratio> 50% - Temp. of Gas at Gasifier Outlet300to500 Moisture content(%) <18% - Ash Content <3% - Hot Gas Mode Efficiency >90% - Cold Gas Mode Efficiency >85% Smaller size with easy installation - Simplicity in operation and care of Automation due to absence of log in process control. |

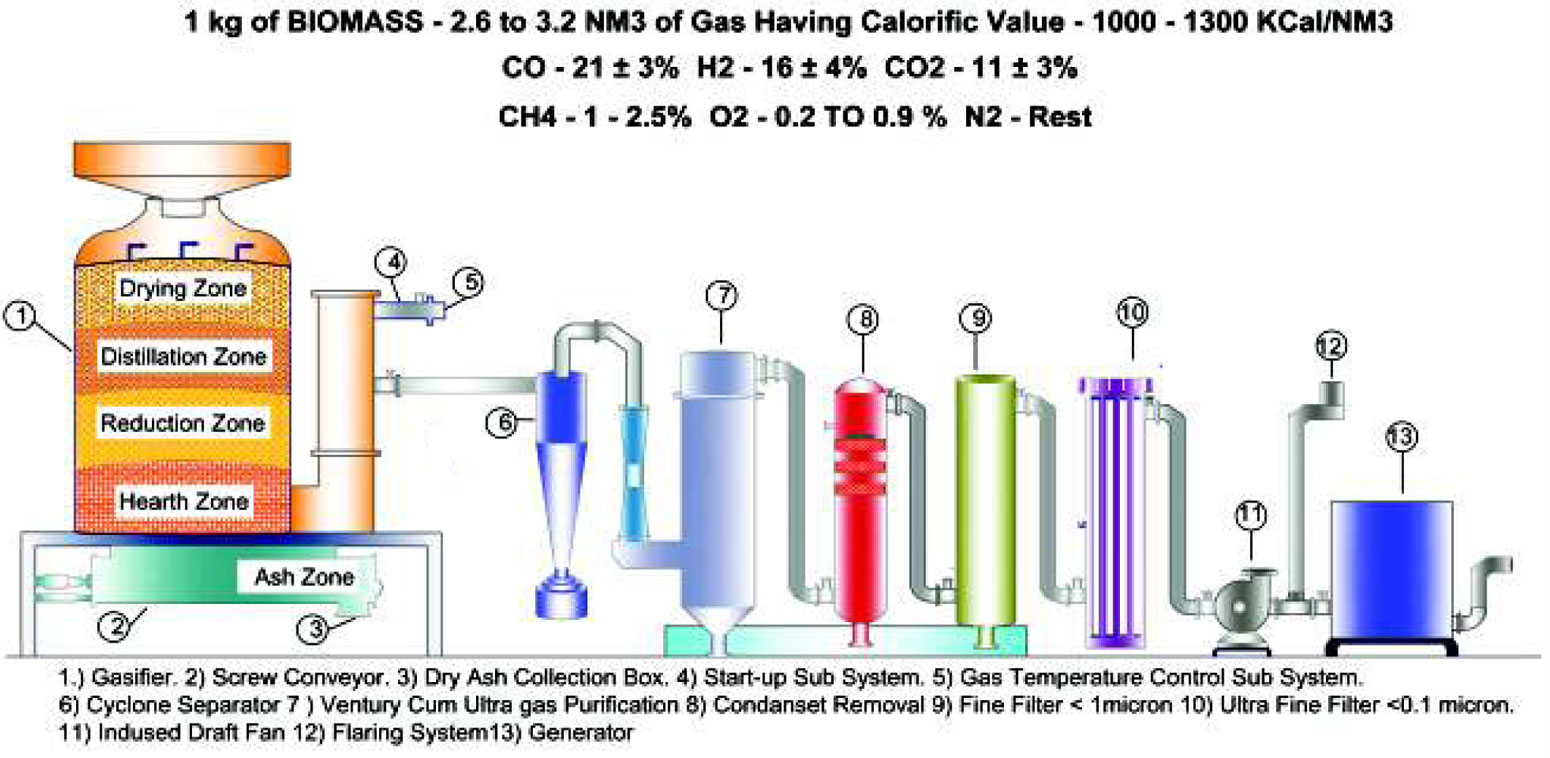

BIOMASS GASSIFIER POWER PLANT COMPRISE OF FOLLOWING:

A.Gasification Plant

B.Power Package

C.Auxiliaries

A. Gasification Plant |

||||

| GASSIFIER REACTOR | : - | Gassifier Reactor is Refractory lined cylindrical Vessle suitable to withstand 1600oC. (a) having reaction zone (b) Combustion Zone (c) Drying Zone (d) Having provision of Central Air Nozzle | ||

| GAS COOLING SYSTEM | : - | Ventury cum Impingement Plate Scrubber for Removal of entrained for particulate matter and cooling of the producer gas to ambient for Engine application | ||

| GAS FILTERING SYSTEM | : - | Shall comprise of Pulse Jet / and Ultra Filteration System to control pollutants down to 0.1 micron | ||

| FLARING SYSTEM | : - | Flaring of Gas in case of Emergency shut off | ||

B. Power Package |

||||

Instrumentation & Control |

||||

| a. Gas Flow meter b. Pressure indications c. Temperature monitoring the Reactor d. Automatic Retraction of to pcover e. Automatic Start / stop of bucket elevator f. Control of quality of gas feed into engineer g. Automatic Char/ ash extraction h. Monitoring of relevant such as Pressure along gas flow I. Gas consumption Monitoring j. Gas Pressure and Temp. monitoring. | ||||

Control & Safeties |

||||

| a. Oxygen Monitoring & Indication for leakage into air - b.Water seal Provision to release pressure in event of extra pressurization c. Automation for start automatic retraction of top cover with pneumatic loader d.Automatic positioning of two way chute e .Provision of Ultra sonic sensor for cut on and cut off of Biomass loading f. Automatic control of Air Blower spped to meet engine requirement g. Automatic Emergencey flaring etc. h. Automatic Emergency shut down of Reactor | ||||

Computerized Data & Acquisition |

||||

| a. Reactor Temp. at different zones b. Biomass consumption rate c. Gas Flow Rate | ||||

C. Auxiliaries |

||||

| a. Biomass Sizing System b. Biomass Transportation system c. Biomass Conveying System d. Water Treatment Plant g. Cooling Tower e. Char Extraction Unit |

||||